Vector Cad Cam S

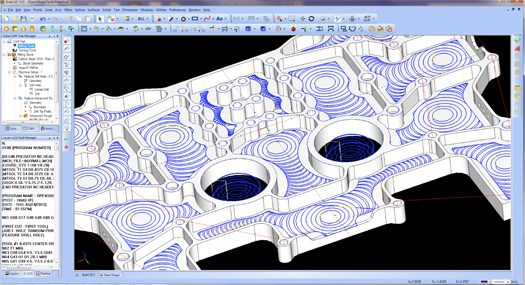

VectorCadCamS Glossary of Key Terminology Used in Printed Circuit Board. PCB Design and Manufacturing. We have a. new glossary. While the new glossary is being developed and tested, this legacy glossary is. A collection of words with their meanings. This glossary has. PCB design and manufacturing, with rudimentary. The words have other meanings not given here. For. those, consult. Keygen 5000. English language or electronics dictionary. Recommended dictionaries. Do you need. on line definitions. A component which adds energy to the signal it passes. A device that requires an external source of power to operate. Any device that switches or amplifies by the. CEREC-krona.jpg' alt='Vector Cad Cam S' title='Vector Cad Cam S' />Pdf2cad converts PDF to CADCAM formats DXF, DWG and HPGL. SketchUp is 3D modeling software thats easy to learn and incredibly fun to use. Download SketchUp today for free and get started drawing in 3D. CAD sites organized into top ten lists, covering all major CAD software packages, plus industries, CAD jobs, tutorials, and tips and tricks. Fast robotic plasma cutting table for metal automatic software functions link drawing entities together, clean up messy drawings, offset for torch kerf width, draw. Download a free trial of Fusion 360, online CADCAM design software that connects your entire product design development process. Computervision, Inc. CV was an early pioneer in Computer Aided Design and Manufacturing CADCAM. Computervision was founded in 1969 by Marty Allen and Philippe. Examples. of active devices which fit one or more of the above definitions. ICs. Contrast with. Aluminum Nitride, a compound of aluminum with nitrogen. A ceramic used for insulators in electron tubes or substrates in. It can withstand continuously high temperatures and has a. Aluminum oxide Al. A circuit in which the output varies as a continuous function. The positive element such as the plate of a vacuum tube. In a. cathode ray tube, the electrodes connected to a source of positive. These anodes are used to concentrate and accelerate the electron beam. Graf. 1. An indexed shape with a specified x and y dimension, or. The index of the. Position. a number used in an aperture list to identify an aperture. D code. 2. A small, thin, trapezoidal piece of plastic used to limit and shape. A vector photoplotter plots images from a. A line of textual data in an. D code and position, the shape, the usage. X and Y dimensions of an. Some aperture lists leave out certain of those types of data. For. example. laser photoplotters dont need to know whether an aperture is a flash. An. ASCII text. data file which describes the size and shape of the apertures used by a. A print out of this file. Also called aperture table. Aperture list. A component of a. Its center hole is attached to a motorized spindle on the lamp head. When a. D code. denoting a particular position on the wheel is retreived from a. Gerber file. by the photoplotter, the wheel is caused to rotate so that the aperture. In preparation for a photoplotting, the aperture wheel is set up by a. This process. is subject. Artwork for printed circuit design is photoplotted film or. Gerber files used to drive the photoplotter, NC Drill file and. See also. Valuable Final Artwork. American Standard Code for Information Interchange. A. text and. control code character set used in computers. Pronounced. ASS key. Note The following description is excerpted from FOLDOC,. Free Online. Dictionary of Computing. The links in this definition point to FOLDOC. Open link in new tab. ASCII. is the basis of character sets used in almost all present day. US ASCII. uses only the lower seven. A Z. More modern coded character sets e. Latin 1. Unicode. ASCII for values. Latin. characters like. German ess tsett, characters. Latin writing systems e. Cyrillic, or. Han characters. ASCII character set. Latin 1, an extension to 2. US ASCII. 1. 28 character set, has been provided online by Paul Lutus at. Arachnoid. com. A thoroughly unoffical subset of. US ASCII. which contains the space character, numbers, most basic punctuation, and. A Z, but lacks the. The process of positioning and soldering components to a. PCB. 2. Act or process of fitting together parts to make a. A drawing depicting the locations of components, with their. Also called component locator drawing. A manufacturing facility for attaching and soldering components. Aka assembler and also CM, for contract manufacturer. American Society of Testing and Materials. Automatic Test Equipment. See also. DUT. American Wire Gauge. A PCB Designer needs to know diameters. E pads. The American Wire Gauge, formerly known as the Brown and Sharpe. B S. Gauge, originated in the wire drawing industry. The gauge is. calculated. From this basic relationship, the following rules can be. ASTM. data by Global Wire Group. PC board design or a silicon chip design automatically. Abbrev. BGA. flip chip. PCB footprint. PCB are heated in a reflow oven. Advantages of the. QFP. and thus has a long shelf life. Disadvantages of the. BGA. are 1 they, or their solder joints, are subject to stress related. For example, the intense vibration of rocket powered space vehicles can. PCB, 2 they can not be hand soldered they require. The electrode of a transistor which controls the movements of. It is the element which. A metal beam flat metallic lead which extends from the edge of a. Upon separation of the individual die normally by chemical. This method is an example of. Graf. Ball Grid Array. Also, a CAD file which represents the. Board vendor. A manufacturer of printed circuit boards. Aka. fabricator. The portion of an electronic component exclusive of its pins or. Bill of Materials. A list of components to be. For a PCB the. BOM. A. BOM. is used for ordering parts and, along with an. Controlled Collapsed Chip Connect. A type of. flip chip. Intels Pentium III. Motorolas. Power. PC 6. 03 and Power. PC 6. 04 RISC Microprocessors. Here is an. Friday, February 0. C4CBGA interconnect technology. Kromann, Gerke and Huang of Motorolas Advanced Packaging Technology. Division. Computer Aided Design. A system where engineers create a design. In electronics, the result would be a printed. Simply a concatenation of the two terms. Operations Manual For Rosengrens Skafferi more. CAD. CAM. Computer Assisted Engineering. In electronics work, CAE refers to. Conductive Anodic Filamentation or Conductive Anodic Filament. An electrical short which occurs in. PCBs. when a conductive filament forms in the laminate dielectric material. CAF. is a potentially dangerous source of electrical failure in the PCB. PCB designs have increased in density, with hole to hole spacings. CAF. has become an everyday concern. Erik J. Bergum, CAF. Resistance. of NON. DICY. FR 4,. PC FAB. Computer Aided Manufacturing. See. CAM files. CAM means Computer Aided Manufacturing. These are the data files. The types of. CAM files. Gerber file, which controls a photoplotter, 2 NC Drill file. NC Drill machine and 3 fab and assembly drawings in soft. CAM files represent the valuable final product of. They are handed off to the board house which further refines and. CAM data in their processes, for example in step and repeat. Some PCB design software companies refer to all plotter or. CAM files., although some of the plots may be check plots which are not used in. To draw schematics with CAE software in such a way that. The. extracted data. BOM. The more useful the data that is included in the schematic, the more. BOM and netlist extracted from it will be. Extract data from a CAE schematic. E. g. Capture. The process of creating a CAE drawing containing intelligent data. E. G. Schematic capture. A connector which is fabricated as an integral portion of a printed. Often employed to enable a daughter or. See. finger. Extract information automatically through the use of software, as. In an electron tube the electrode through which a primary. General name for. When a semiconductor diode is biased in. In electrolytic plating, the. Graf. Ceramic Ball Grid Array. NEMA. grade of industrial laminate having a substrate of woven glass surfaces. It has good electrical. FR 4. Pen plots that are suitable for checking only. Pads are represented. This technique is used to enhance transparency of multiple layers. An integrated circuit manufactured on a semiconductor substrate. Also called a. die. Computer aided design Wikipedia. Computer aided design CAD is the use of computer systems or workstations to aid in the creation, modification, analysis, or optimization of a design. CAD software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The term CADD for Computer Aided Design and Drafting is also used. Its use in designing electronic systems is known as electronic design automation, or EDA. In mechanical design it is known as mechanical design automation MDA or computer aided drafting CAD, which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector based graphics to depict the objects of traditional drafting, or may also produce raster graphics showing the overall appearance of designed objects. However, it involves more than just shapes. As in the manual drafting of technical and engineering drawings, the output of CAD must convey information, such as materials, processes, dimensions, and tolerances, according to application specific conventions. CAD may be used to design curves and figures in two dimensional 2. D space or curves, surfaces, and solids in three dimensional 3. D space. 5CAD is an important industrial art extensively used in many applications, including automotive, shipbuilding, and aerospace industries, industrial and architectural design, prosthetics, and many more. CAD is also widely used to produce computer animation for special effects in movies, advertising and technical manuals, often called DCC digital content creation. The modern ubiquity and power of computers means that even perfume bottles and shampoo dispensers are designed using techniques unheard of by engineers of the 1. Because of its enormous economic importance, CAD has been a major driving force for research in computational geometry, computer graphics both hardware and software, and discrete differential geometry. The design of geometric models for object shapes, in particular, is occasionally called computer aided geometric design CAGD. Overview of CAD softwareeditStarting around the mid 1. CAD became apparent. The benefits of CAD systems over manual drafting are the capabilities one often takes for granted from computer systems today automated generation of Bill of Material, auto layout in integrated circuits, interference checking, and many others. Eventually CAD provided the designer with the ability to perform engineering calculations. During this transition, calculations were still performed either by hand or by those individuals who could run computer programs. CAD was a revolutionary change in the engineering industry, where draftsmen, designers and engineering roles begin to merge. It did not eliminate departments, as much as it merged departments and empowered draftsman, designers and engineers. CAD is just another example of the pervasive effect computers were beginning to have on industry. Current computer aided design software packages range from 2. D vector based drafting systems to 3. D solid and surface modelers. Modern CAD packages can also frequently allow rotations in three dimensions, allowing viewing of a designed object from any desired angle, even from the inside looking out. Some CAD software is capable of dynamic mathematical modeling. CAD technology is used in the design of tools and machinery and in the drafting and design of all types of buildings, from small residential types houses to the largest commercial and industrial structures hospitals and factories. CAD is mainly used for detailed engineering of 3. D models or 2. D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components. It can also be used to design objects such as jewelry, furniture, appliances, etc. Furthermore, many CAD applications now offer advanced rendering and animation capabilities so engineers can better visualize their product designs. D BIM is a type of virtual construction engineering simulation incorporating time or schedule related information for project management. CAD has become an especially important technology within the scope of computer aided technologies, with benefits such as lower product development costs and a greatly shortened design cycle. CAD enables designers to layout and develop work on screen, print it out and save it for future editing, saving time on their drawings. Computer aided design is one of the many tools used by engineers and designers and is used in many ways depending on the profession of the user and the type of software in question. CAD is one part of the whole Digital Product Development DPD activity within the Product Lifecycle Management PLM processes, and as such is used together with other tools, which are either integrated modules or stand alone products, such as CAD is also used for the accurate creation of photo simulations that are often required in the preparation of Environmental Impact Reports, in which computer aided designs of intended buildings are superimposed into photographs of existing environments to represent what that locale will be like, where the proposed facilities are allowed to be built. Potential blockage of view corridors and shadow studies are also frequently analyzed through the use of CAD. CAD has been proven to be useful to engineers as well. Using four properties which are history, features, parameterization, and high level constraints. The construction history can be used to look back into the models personal features and work on the single area rather than the whole model. Parameters and constraints can be used to determine the size, shape, and other properties of the different modeling elements. The features in the CAD system can be used for the variety of tools for measurement such as tensile strength, yield strength, electrical or electro magnetic properties. Also its stress, strain, timing or how the element gets affected in certain temperatures, etc. There are several different types of CAD,9 each requiring the operator to think differently about how to use them and design their virtual components in a different manner for each. There are many producers of the lower end 2. D systems, including a number of free and open source programs. These provide an approach to the drawing process without all the fuss over scale and placement on the drawing sheet that accompanied hand drafting, since these can be adjusted as required during the creation of the final draft. D wireframe is basically an extension of 2. D drafting not often used today. Each line has to be manually inserted into the drawing. The final product has no mass properties associated with it and cannot have features directly added to it, such as holes. The operator approaches these in a similar fashion to the 2. D systems, although many 3. D systems allow using the wireframe model to make the final engineering drawing views. D dumb solids are created in a way analogous to manipulations of real world objects not often used today.

Glossary of Key Terminology Used in Printed Circuit Board. PCB Design and Manufacturing. We have a. new glossary. While the new glossary is being developed and tested, this legacy glossary is. A collection of words with their meanings. This glossary has. PCB design and manufacturing, with rudimentary. The words have other meanings not given here. For. those, consult. Keygen 5000. English language or electronics dictionary. Recommended dictionaries. Do you need. on line definitions. A component which adds energy to the signal it passes. A device that requires an external source of power to operate. Any device that switches or amplifies by the. CEREC-krona.jpg' alt='Vector Cad Cam S' title='Vector Cad Cam S' />Pdf2cad converts PDF to CADCAM formats DXF, DWG and HPGL. SketchUp is 3D modeling software thats easy to learn and incredibly fun to use. Download SketchUp today for free and get started drawing in 3D. CAD sites organized into top ten lists, covering all major CAD software packages, plus industries, CAD jobs, tutorials, and tips and tricks. Fast robotic plasma cutting table for metal automatic software functions link drawing entities together, clean up messy drawings, offset for torch kerf width, draw. Download a free trial of Fusion 360, online CADCAM design software that connects your entire product design development process. Computervision, Inc. CV was an early pioneer in Computer Aided Design and Manufacturing CADCAM. Computervision was founded in 1969 by Marty Allen and Philippe. Examples. of active devices which fit one or more of the above definitions. ICs. Contrast with. Aluminum Nitride, a compound of aluminum with nitrogen. A ceramic used for insulators in electron tubes or substrates in. It can withstand continuously high temperatures and has a. Aluminum oxide Al. A circuit in which the output varies as a continuous function. The positive element such as the plate of a vacuum tube. In a. cathode ray tube, the electrodes connected to a source of positive. These anodes are used to concentrate and accelerate the electron beam. Graf. 1. An indexed shape with a specified x and y dimension, or. The index of the. Position. a number used in an aperture list to identify an aperture. D code. 2. A small, thin, trapezoidal piece of plastic used to limit and shape. A vector photoplotter plots images from a. A line of textual data in an. D code and position, the shape, the usage. X and Y dimensions of an. Some aperture lists leave out certain of those types of data. For. example. laser photoplotters dont need to know whether an aperture is a flash. An. ASCII text. data file which describes the size and shape of the apertures used by a. A print out of this file. Also called aperture table. Aperture list. A component of a. Its center hole is attached to a motorized spindle on the lamp head. When a. D code. denoting a particular position on the wheel is retreived from a. Gerber file. by the photoplotter, the wheel is caused to rotate so that the aperture. In preparation for a photoplotting, the aperture wheel is set up by a. This process. is subject. Artwork for printed circuit design is photoplotted film or. Gerber files used to drive the photoplotter, NC Drill file and. See also. Valuable Final Artwork. American Standard Code for Information Interchange. A. text and. control code character set used in computers. Pronounced. ASS key. Note The following description is excerpted from FOLDOC,. Free Online. Dictionary of Computing. The links in this definition point to FOLDOC. Open link in new tab. ASCII. is the basis of character sets used in almost all present day. US ASCII. uses only the lower seven. A Z. More modern coded character sets e. Latin 1. Unicode. ASCII for values. Latin. characters like. German ess tsett, characters. Latin writing systems e. Cyrillic, or. Han characters. ASCII character set. Latin 1, an extension to 2. US ASCII. 1. 28 character set, has been provided online by Paul Lutus at. Arachnoid. com. A thoroughly unoffical subset of. US ASCII. which contains the space character, numbers, most basic punctuation, and. A Z, but lacks the. The process of positioning and soldering components to a. PCB. 2. Act or process of fitting together parts to make a. A drawing depicting the locations of components, with their. Also called component locator drawing. A manufacturing facility for attaching and soldering components. Aka assembler and also CM, for contract manufacturer. American Society of Testing and Materials. Automatic Test Equipment. See also. DUT. American Wire Gauge. A PCB Designer needs to know diameters. E pads. The American Wire Gauge, formerly known as the Brown and Sharpe. B S. Gauge, originated in the wire drawing industry. The gauge is. calculated. From this basic relationship, the following rules can be. ASTM. data by Global Wire Group. PC board design or a silicon chip design automatically. Abbrev. BGA. flip chip. PCB footprint. PCB are heated in a reflow oven. Advantages of the. QFP. and thus has a long shelf life. Disadvantages of the. BGA. are 1 they, or their solder joints, are subject to stress related. For example, the intense vibration of rocket powered space vehicles can. PCB, 2 they can not be hand soldered they require. The electrode of a transistor which controls the movements of. It is the element which. A metal beam flat metallic lead which extends from the edge of a. Upon separation of the individual die normally by chemical. This method is an example of. Graf. Ball Grid Array. Also, a CAD file which represents the. Board vendor. A manufacturer of printed circuit boards. Aka. fabricator. The portion of an electronic component exclusive of its pins or. Bill of Materials. A list of components to be. For a PCB the. BOM. A. BOM. is used for ordering parts and, along with an. Controlled Collapsed Chip Connect. A type of. flip chip. Intels Pentium III. Motorolas. Power. PC 6. 03 and Power. PC 6. 04 RISC Microprocessors. Here is an. Friday, February 0. C4CBGA interconnect technology. Kromann, Gerke and Huang of Motorolas Advanced Packaging Technology. Division. Computer Aided Design. A system where engineers create a design. In electronics, the result would be a printed. Simply a concatenation of the two terms. Operations Manual For Rosengrens Skafferi more. CAD. CAM. Computer Assisted Engineering. In electronics work, CAE refers to. Conductive Anodic Filamentation or Conductive Anodic Filament. An electrical short which occurs in. PCBs. when a conductive filament forms in the laminate dielectric material. CAF. is a potentially dangerous source of electrical failure in the PCB. PCB designs have increased in density, with hole to hole spacings. CAF. has become an everyday concern. Erik J. Bergum, CAF. Resistance. of NON. DICY. FR 4,. PC FAB. Computer Aided Manufacturing. See. CAM files. CAM means Computer Aided Manufacturing. These are the data files. The types of. CAM files. Gerber file, which controls a photoplotter, 2 NC Drill file. NC Drill machine and 3 fab and assembly drawings in soft. CAM files represent the valuable final product of. They are handed off to the board house which further refines and. CAM data in their processes, for example in step and repeat. Some PCB design software companies refer to all plotter or. CAM files., although some of the plots may be check plots which are not used in. To draw schematics with CAE software in such a way that. The. extracted data. BOM. The more useful the data that is included in the schematic, the more. BOM and netlist extracted from it will be. Extract data from a CAE schematic. E. g. Capture. The process of creating a CAE drawing containing intelligent data. E. G. Schematic capture. A connector which is fabricated as an integral portion of a printed. Often employed to enable a daughter or. See. finger. Extract information automatically through the use of software, as. In an electron tube the electrode through which a primary. General name for. When a semiconductor diode is biased in. In electrolytic plating, the. Graf. Ceramic Ball Grid Array. NEMA. grade of industrial laminate having a substrate of woven glass surfaces. It has good electrical. FR 4. Pen plots that are suitable for checking only. Pads are represented. This technique is used to enhance transparency of multiple layers. An integrated circuit manufactured on a semiconductor substrate. Also called a. die. Computer aided design Wikipedia. Computer aided design CAD is the use of computer systems or workstations to aid in the creation, modification, analysis, or optimization of a design. CAD software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The term CADD for Computer Aided Design and Drafting is also used. Its use in designing electronic systems is known as electronic design automation, or EDA. In mechanical design it is known as mechanical design automation MDA or computer aided drafting CAD, which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector based graphics to depict the objects of traditional drafting, or may also produce raster graphics showing the overall appearance of designed objects. However, it involves more than just shapes. As in the manual drafting of technical and engineering drawings, the output of CAD must convey information, such as materials, processes, dimensions, and tolerances, according to application specific conventions. CAD may be used to design curves and figures in two dimensional 2. D space or curves, surfaces, and solids in three dimensional 3. D space. 5CAD is an important industrial art extensively used in many applications, including automotive, shipbuilding, and aerospace industries, industrial and architectural design, prosthetics, and many more. CAD is also widely used to produce computer animation for special effects in movies, advertising and technical manuals, often called DCC digital content creation. The modern ubiquity and power of computers means that even perfume bottles and shampoo dispensers are designed using techniques unheard of by engineers of the 1. Because of its enormous economic importance, CAD has been a major driving force for research in computational geometry, computer graphics both hardware and software, and discrete differential geometry. The design of geometric models for object shapes, in particular, is occasionally called computer aided geometric design CAGD. Overview of CAD softwareeditStarting around the mid 1. CAD became apparent. The benefits of CAD systems over manual drafting are the capabilities one often takes for granted from computer systems today automated generation of Bill of Material, auto layout in integrated circuits, interference checking, and many others. Eventually CAD provided the designer with the ability to perform engineering calculations. During this transition, calculations were still performed either by hand or by those individuals who could run computer programs. CAD was a revolutionary change in the engineering industry, where draftsmen, designers and engineering roles begin to merge. It did not eliminate departments, as much as it merged departments and empowered draftsman, designers and engineers. CAD is just another example of the pervasive effect computers were beginning to have on industry. Current computer aided design software packages range from 2. D vector based drafting systems to 3. D solid and surface modelers. Modern CAD packages can also frequently allow rotations in three dimensions, allowing viewing of a designed object from any desired angle, even from the inside looking out. Some CAD software is capable of dynamic mathematical modeling. CAD technology is used in the design of tools and machinery and in the drafting and design of all types of buildings, from small residential types houses to the largest commercial and industrial structures hospitals and factories. CAD is mainly used for detailed engineering of 3. D models or 2. D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components. It can also be used to design objects such as jewelry, furniture, appliances, etc. Furthermore, many CAD applications now offer advanced rendering and animation capabilities so engineers can better visualize their product designs. D BIM is a type of virtual construction engineering simulation incorporating time or schedule related information for project management. CAD has become an especially important technology within the scope of computer aided technologies, with benefits such as lower product development costs and a greatly shortened design cycle. CAD enables designers to layout and develop work on screen, print it out and save it for future editing, saving time on their drawings. Computer aided design is one of the many tools used by engineers and designers and is used in many ways depending on the profession of the user and the type of software in question. CAD is one part of the whole Digital Product Development DPD activity within the Product Lifecycle Management PLM processes, and as such is used together with other tools, which are either integrated modules or stand alone products, such as CAD is also used for the accurate creation of photo simulations that are often required in the preparation of Environmental Impact Reports, in which computer aided designs of intended buildings are superimposed into photographs of existing environments to represent what that locale will be like, where the proposed facilities are allowed to be built. Potential blockage of view corridors and shadow studies are also frequently analyzed through the use of CAD. CAD has been proven to be useful to engineers as well. Using four properties which are history, features, parameterization, and high level constraints. The construction history can be used to look back into the models personal features and work on the single area rather than the whole model. Parameters and constraints can be used to determine the size, shape, and other properties of the different modeling elements. The features in the CAD system can be used for the variety of tools for measurement such as tensile strength, yield strength, electrical or electro magnetic properties. Also its stress, strain, timing or how the element gets affected in certain temperatures, etc. There are several different types of CAD,9 each requiring the operator to think differently about how to use them and design their virtual components in a different manner for each. There are many producers of the lower end 2. D systems, including a number of free and open source programs. These provide an approach to the drawing process without all the fuss over scale and placement on the drawing sheet that accompanied hand drafting, since these can be adjusted as required during the creation of the final draft. D wireframe is basically an extension of 2. D drafting not often used today. Each line has to be manually inserted into the drawing. The final product has no mass properties associated with it and cannot have features directly added to it, such as holes. The operator approaches these in a similar fashion to the 2. D systems, although many 3. D systems allow using the wireframe model to make the final engineering drawing views. D dumb solids are created in a way analogous to manipulations of real world objects not often used today.